6.0L Powerstroke High Pressure Oil Rail Repair Kit

- fits 2003 - 2010 -

Are you experiencing repeat failure of the high pressure oil inlet o-ring on 6.0L injectors? The often-overlooked cause of this problem is the ball tube o-ring in the high pressure oil rail. If close examination of the failed injector seal indicates that it was eroded from the top to the bottom, then the root cause is in the high pressure oil rail. Until recently, this rail was not a serviceable part and required replacement as an assembly at great expense. We now have the parts and tools available to correctly perform this repair and prevent costly comebacks.

Any time the valve covers are removed from a 6.0L engine you should check the oil rails for leaks. This can be done by removing the ICP sensor and pressurizing the system with shop air. You will need to command the IPR valve closed with a scan tool in order to build pressure in the system. Frequently you will find leaks between the ball tube and the oil rail. If there is a leak at one ball tube it is probably wise to replace them all. Even if you do not find any leaks during air testing, it is wise to closely inspect the nipple portion of the ball tube where it inserts into the fuel injector. Even the slightest surface imperfections here are not acceptable. Since pressure in the high pressure oil system can exceed 3,500 PSI even slight surface abnormalities can result in problems over time.

Note that if your injector high pressure oil inlet seals have failed you do NOT have to replace the injectors - see our 6.0L Powerstroke Diesel Injector Seal Kit instead. Our ball tube orings are made from a higher temperature Viton material to prevent repeat failure.

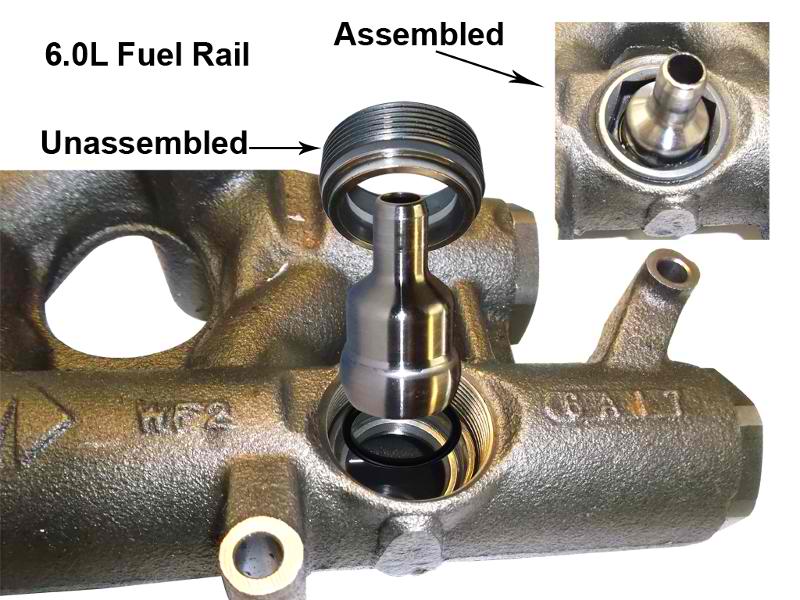

Performing the ball tube / oring repair requires a special tool to remove and replace the hex compression ring. The tool also aligns and centers the ball tube to the rail during the reassembly process. This tool is a one-time investment that can be used over and over again.

Our ball tube removal tool is significantly beefier than most other tools found on the market to withstand the extreme forces sometimes required to loosen the retaining nuts. One of the key features is that it fits directly onto a 1/2 inch drive tool - no socket required. (Many competitive tools require a 23mm socket which is an unusual size not included in many socket sets.) Eliminating the extra looseness between a socket and the tool itself makes impact tools much more effective.

Made in the USA